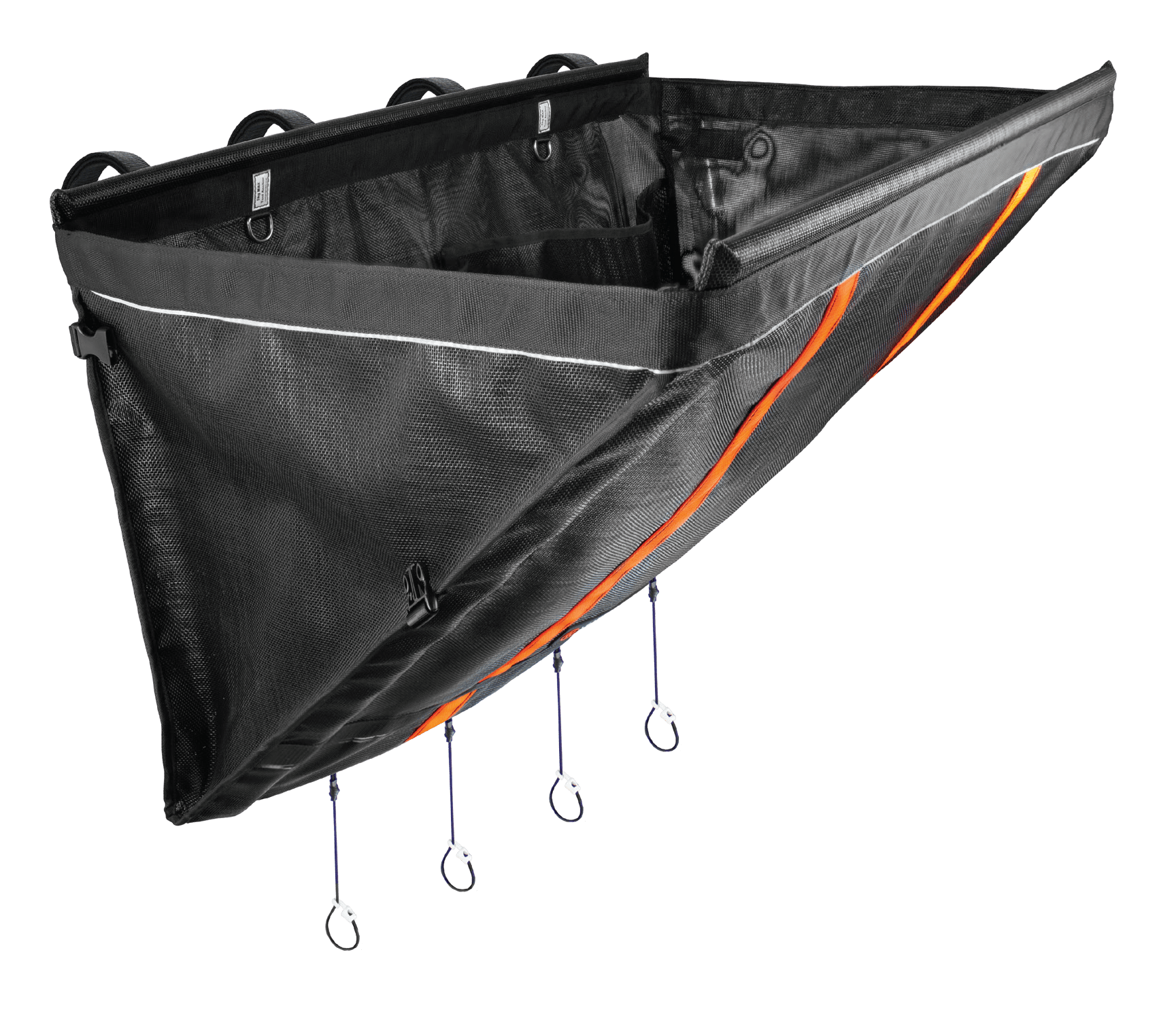

Skynet Materials & Debris Handrail Catch Bag

SKU: TB-SKYNWLL: 40 kg

£0.00

The Skynet Materials & Debris Handrail Catch-Bag is a portable materials and debris collective protection net, designed to easily retro-fit onto cherry pickers, booms, scissors lifts, platforms and railings.

| SKU | Size | Quantity | |

|---|---|---|---|

| TB-SKYN-S | Standard |

|

|

| TB-SKYN-L | Large |

|

The Skynet Materials & Debris Handrail Catch-Bag is a portable materials and debris collective protection net, designed to easily retro-fit onto cherry pickers, booms, scissors lifts, platforms and railings. It is made entirely from structural reinforced mesh that massively decreases weight and windage. The wedged shape also reduces surface area, which makes it more aerodynamic and enables it to be folded into a closed position. This means it can be easily transported, deployed and unobtrusively left in place when not in use. Its high capacity is achieved through a single seamless panel supported by two independent webbing straps that run through the body of the whole net.

• Retro-fit

• Seamless base

• Collapsible/Portable

• Reduced windage

AVAILABLE IN THE FOLLOWING:

Large – Volume: 287L / Height: 85cm / Width: 147cm / Depth: 65cm / Weight: 5Kg

Standard – Volume: 192L / Height: 85cm / Width: 97cm / Depth: 65cm / Weight: 3.4Kg

WLL 40kg

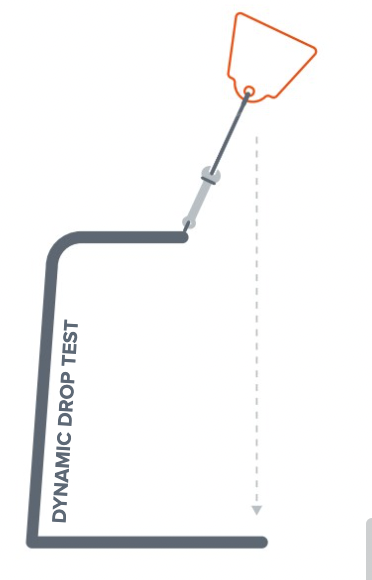

Every item that leaves our factory comes with full documentation containing technical specifications, serial numbers, testing methods, working load limits and inspection results proving it has passed all necessary requirements for work at height.