Pro Shank Tether

SKU: TT-SHANK-PWLL: 2.5 kg

£0.00

The Pro Shank Tether is a semi-permanent tool tether for all tool handle shapes and configurations.

| SKU | Size | Quantity | |

|---|---|---|---|

| TT-SHANK-P-S | Small |

|

|

| TT-SHANK-P-M | Medium |

|

|

| TT-SHANK-P-L | Large |

|

|

| TT-SHANK-P-PP | Pro Pack |

|

|

| TT-SHANK-P-UP | Utility Pro Pack |

|

The Pro Shank Tether is a semi-permanent tool tether for all tool handle shapes and configurations.

• Semi-permanent

• Easily retrofit existing tools

AVAILABLE IN THE FOLLOWING:

Large – Sleeve 15cm / Ø 20-55mm

Medium – Sleeve 13cm / Ø 20-45mm

Small – Sleeve 10cm / Ø 15-35mm

Pro Pack – 20 x small, 20 x medium, 10 x large Semi-permanent

Utility Pro Pack – 200 x small, 200 x medium, 100 x large Semi-permanent

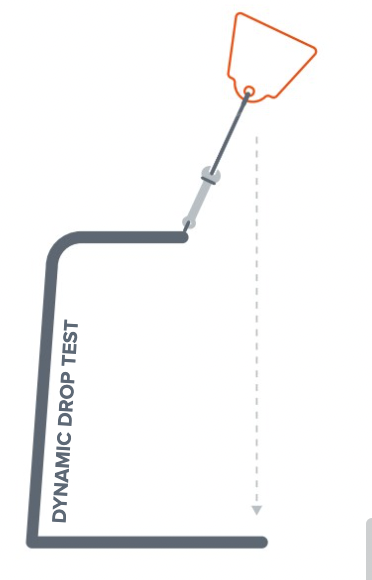

WLL 2.5kg

Every item that leaves our factory comes with full documentation containing technical specifications, serial numbers, testing methods, working load limits and inspection results proving it has passed all necessary requirements for work at height.