LV Pro Pig Bucket

SKU: TB-LVPIG-PROWLL: 45 kg

£0.00

The LV Pro Pig Bucket is the ultimate tool and materials bucket, with a number of advancements over the standard LV Pig.

| SKU | Size | Quantity | |

|---|---|---|---|

| TB-LVPIG-PRO-D | N/A |

|

|

| TB-LVPIG-PRO-D-CS | N/A |

|

The LV Pro Pig Bucket is the ultimate tool and materials bucket, with a number of advancements over the standard LV Pig. Firstly, it has 8 external pockets with dedicated anchorage points, offset to keep your lanyards neatly to one side. Secondly, it has 4 large external reinforced tool frogs, which accommodate large tools of all shapes and sizes. There is also an internal tool frog divider, which structurally supports the bag, separates your contents and allows you to holster a variety of smaller hand tools too. An optional drawstring closure system protects your contents from bad weather and spillage.

• High visibility

• Intrinsically safe

• Breathable

• Lifting/Carry strap, detachable shoulder strap

• 13 x Tool frogs

• 12 x D-ring tethering points

• Optional drawstring closure

Volume: 22L / Height: 36cm / Diameter: Ø 28cm / Weight: 1.55Kg

WLL 45kg

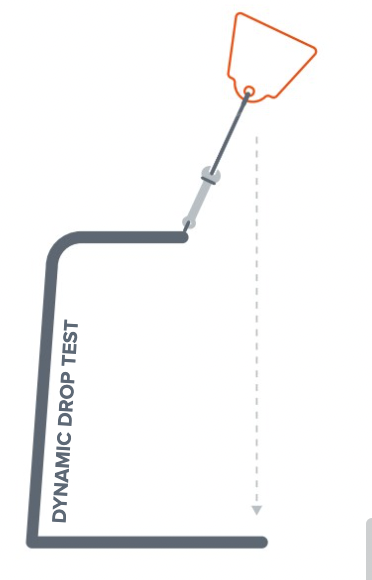

Every item that leaves our factory comes with full documentation containing technical specifications, serial numbers, testing methods, working load limits and inspection results proving it has passed all necessary requirements for work at height.