Aerial Rucksack

SKU: TB-RSACKWLL: 25 kg

£0.00

The Aerial Rucksack packs a lot of technology into a simple design. It allows you to tether your tools to the internal tethering points, climb to your work area and secure the bag to a fixing point/structure via the large external structural D-ring.

| SKU | Size | Quantity | |

|---|---|---|---|

| TB-RSACK | Single |

|

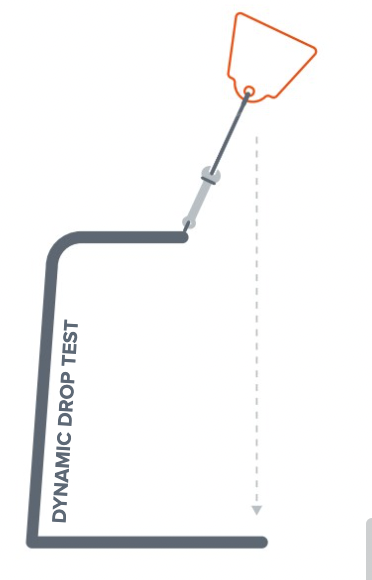

The Aerial Rucksack packs a lot of technology into a simple design. It allows you to tether your tools to the internal tethering points, climb to your work area and secure the bag to a fixing point/structure via the large external structural D-ring. The clam-style opening then gives you maximum access, allowing you to safely use your tethered tools directly from the bag. It is heavily reinforced for intense daily usage in commercial applications and features an advanced AirMat back panel made from a silver-coated anti-bacterial marine cushioning material that holds shape, improves airflow and breathability and greatly reduces moisture built up. The perfect choice for a tool back pack.

• Breathable AirMat back panel

• Padded shoulder straps and top carry handle

• Internal and external pockets

• Clam-style opening

• 6 x D-ring tethering points

• External anchorage D-ring

Volume: 37L / Height: 45cm / Width: 38cm / Depth: 17cm / Weight: 1.6Kg

WLL 25kg

Every item that leaves our factory comes with full documentation containing technical specifications, serial numbers, testing methods, working load limits and inspection results proving it has passed all necessary requirements for work at height.