Shank Tether

SKU: TT-SHANKWLL: 1 kg

£0.00

The Shank Tether is a semi- permanent tool tether for shaped handles (preformed with a tapered mid-section) or moulded rubber grips.

| SKU | Size | Quantity | |

|---|---|---|---|

| TT-SHANK-S | Small |

|

|

| TT-SHANK-M | Medium |

|

|

| TT-SHANK-L | Large |

|

|

| TT-SHANK-PP | Multi Pack of 50 |

|

|

| TT-SHANK-UP | Multi Pack of 100 |

|

Shanks are the quickest and easiest way to tether your tools. They come pre-assembled with a clear adhesive heat shrink sleeve and structural D-ring anchor point – no separate parts! That means all you have to do is slide it over a tool handle, shaft or grip, apply heat and you’re done. Each shank is colour coded to indicate working load and features heat protected webbing and labels that prevent accidental burning during application.

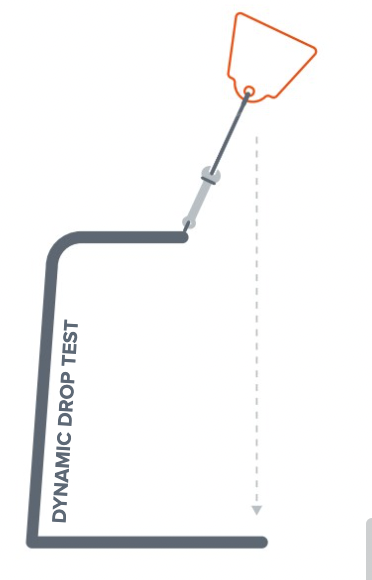

Rating using a 47x safety factor: see Product Testing.