Flush Shackle

SKU: TT-DSHACKWLL: 30 kg

£0.00

The Flush Shackle is designed for shaped tools (spanners, podgers etc). Flush bolt design prevents snagging and provides extra security, moves freely up and down the tool shaft to facilitate holstering and prevent obstruction during operation, and can be made permanent using Loctite.

| SKU | Size | Quantity | |

|---|---|---|---|

| TT-DSHACK-1 | 10 X 20mm Inside Fitting |

|

|

| TT-DSHACK-10 | 26 X 52mm Inside Fitting |

|

|

| TT-DSHACK-2 | 13 X 25mm Inside Fitting |

|

|

| TT-DSHACK-3 | 16 X 32mm Inside Fitting |

|

|

| TT-DSHACK-5 | 10 X 29mm Inside Fitting |

|

|

| TT-DSHACK-4 | 13 X 43mm Inside Fitting |

|

|

| TT-DSHACK-7 | 19 X 55mm Inside Fitting |

|

|

| TT-DSHACK-8 | 19 X 38mm Inside Fitting |

|

|

| TT-DSHACK-9 | 22 X 44mm Inside Fitting |

|

The Flush Shackle is designed for shaped tools (spanners, podgers etc). Flush bolt design prevents snagging and provides extra security, moves freely up and down the tool shaft to facilitate holstering and prevent obstruction during operation, and can be made permanent using Loctite.

WLL 30kg

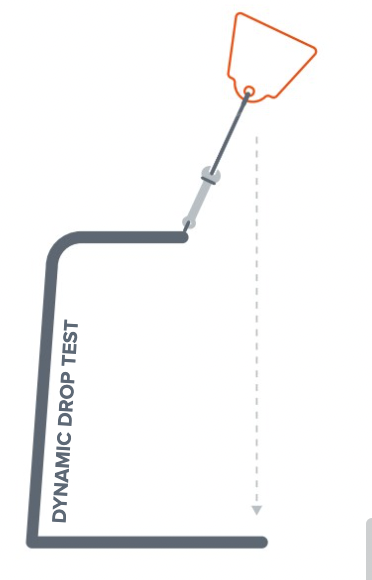

Every item that leaves our factory comes with full documentation containing technical specifications, serial numbers, testing methods, working load limits and inspection results proving it has passed all necessary requirements for work at height.